Practical Electronics

Projects By Mike, K4ICY Practical Electronics

Projects By Mike, K4ICY

Weekend

Radio Click

Here for More Electronics Projects and

Tutorials By

Mike Maynard, K4ICY

.

It

Comes In Any Color You Wish… - Fun with the FULL-COLOR

"RGB" LED

Originally published in The

Printed Circuit, Newsletter of the Tallahassee Amateur

Radio Society, May 2013, page 16

[VISIT HERE]

Edited/Updated December 2023

.

Dimming and Current Control for

LED’s

An

LED (Light Emitting Diode) that comes in every color of the rainbow,

and then some? As a high school youth in a three-year

electronics magnet program surrounded by other youth familiar with, and

very interested in electronics, this kind of 21st century marvel was

science fiction and a ‘Holy Grail’ of LED’s. During our first

year, the only LED colors possible were red and green and anything in

between and not that bright. The blue LED was invented by our

third year and wasn't really usable, but I still remember a few kids

talking about it. I worked for an electronics contract

manufacturer in the early 1990's where I had acquaintance with

electrical engineers and access to any part available. I

dreamt of self-contained Red/Green/Blue LED's and their potential

years before they were reality.

It's hard now [in the

2020's] to imagine the absence of what we now take for granted and that

the major advancements in LED lighting technology are really more

recent. Not only do LED’s come in a wide array of photon

output wavelengths from UV to IR, but many are bright enough to burn

things in their light path and are now ubiquitously used in most

applications of lighting including home lighting, commercial and street

lighting, smart automotive headlamp assemblies and indicator lights,

the main source of illumination for most of our portable devices such

as smartphones and tablets as well as television displays, and on and

on. They also consume a fraction of the power as they are

very efficient, and with that, have been the replacement for all

lighting fixtures with most conventional incandescent lamps illegal to

sell in many countries commercially.

Full-color LED's, now generally called

"RGB's," which are actually three separate LED's housed in

one package, are now a common commodity for decorative lighting, in

living spaces, art and gaming PC's and many have self-contained

microcontroller addressability. There’s not much complexity to

using RGB

LED’s in your own projects. Essentially just diodes, they only

allow

current to pass in one direction. When I first wrote this

article in 2013, RGB LED's were most easily available at Radio Shack

for $3.50 a piece but now you can get them in 100 piece bulk packages

for $9 (or 5 to 10 cents a piece) on Amazon, AliExpress, eBay and etc.

and can be had in many package varieties from 5mm, 3mm, 5050 smd, LED

strips and many types of addressable models. But the basic

5mm RGB LED has four leads with either the anode or cathode of

each individual color element tied together as common.

.

.

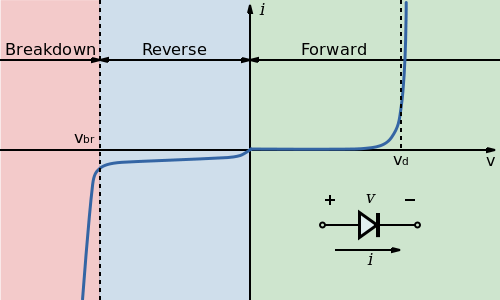

Unlike old-fashioned incandescent

bulbs where you could connect a battery right up to it for light, an

LED is a semiconductor and requires a finite range of voltage and

current allowance to produce light as desired without breaching its

design specs

and burning it out. As you can see by the chart, there is

a non-linearity between voltage applied and the current it

consumes. An LED has to reach an ‘on’ voltage level before it

will emit photons and the value of illuminated light (lumens) is not

constant through the safe voltage range. Also, the amount of

current consumed within the voltage range, typically between 2-3 volts

is not easy to quantify. But as you experiment with one and

use an applicable current-limiting resistor in series, you can get

close.

An LED typically needs a

current-limiting resistor and without it would fail. As an

LED reaches its maximum light output the internal resistance of the LED

is greatly reduced so aside from any method used to ‘dim’ and LED, it’s

going to need a resistor in series with it. But what value

resistor? Figuring what value of current-limiting resistor to

use while getting you the most brightness allowed from an LED takes

knowing what the specification of that LED is along with a small

formula for calculating the value for you particular operating voltage,

but I would suggest using one of the many online LED Resistor

Calculators to save time [Try the one provided by Digi-Key.]

There are two important pieces of information given in the specs for

any LED: forward operating voltage (typ. 2-3 volts,) and maximum

current (mA). The LED’s voltage is the desired voltage when

at or below its rated current max (milliamps.) I would

suggest staying below the rated max amps in the use of an LED, or you

may shorten its life. As a rule of thumb, a typical LED used

in a common 5 volt circuit would require a limiting resistor in the

range of 330 to 1,000 ohms depending on desired brightness.

.

.

If you wish for a quick and easy

formula; use Resistance = (Volts supplied - Foward voltage) / Foward

current [ R = (Vs-Vf) / Af ]. R is the resistance that should

be used to keep your LED running cool and safe but it should be a

common resistor chosen at the next-highest component value.

Vs is the source voltage (ie: 12 volts), and Vf is the load

voltage figure (LED’s rated foward voltage.) So if the data

sheet says that the LED is rated at 2.3 volts for a max of 20 ma (A =

0.02), using the formula, R = 486, or just use a common 560 ohm

resistor or larger. Try some experimenting before using an

LED in a circuit. If the LED gets too warm, you'll need to increase the

resistor's value. Also keep in mind to use a resistor wattage

size capable of handling the current so just use Ohm’s Law.

For example, for a 20 ma LED on a 12 volt circuit at full

brightness you would use a ½ watt resistor, because at the 0.25 watts

of power drawn for it, you would burn up a smaller ¼ watt resistor.

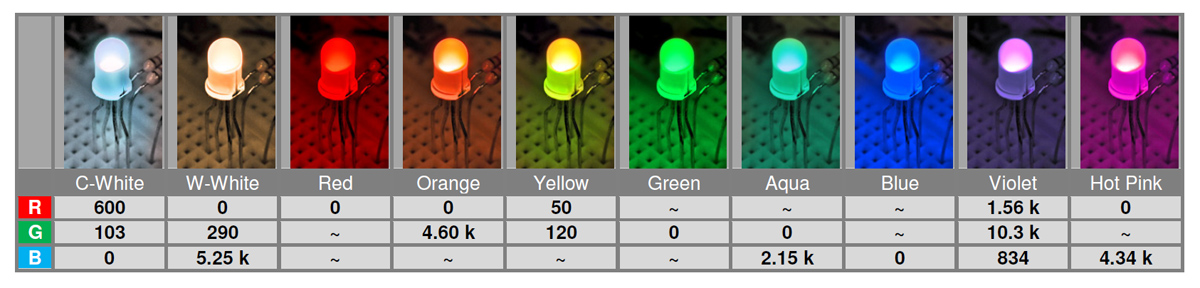

Please note that each color element of an RGB LED will

consume a different amount of current due to each element's material

composition and other factors. Blue and Green LED elements

may consume around 14 ma while the Red may consume over 20 ma.

Working

the Range with Brute Force

Can an LED be dimmed with a

potentiometer? To some degree, you can in fact ‘dim’ or

control the light output of an LED using resistors while working within

its safe operation voltage range. Keep in mind not to reduce

the in-series resistance to less than the chosen limiting resistor

value. So can we use resistors to create any desired color

with an RGB LED? If you look at my schematic you’ll notice

that I have my base-level limiting resistors plus

a potentiometer (pot) in series with each cathode leg of the

LED. By changing the value of each trimmer, by brute force,

we can control the light output level of each internal LED element and

thus control the perceivable color output of the LED. If you

take a look at my experimental LED color chart, each color of LED light

was configured by different resistance values added to the limiting

resistor value of each LED segment. Some very cool results in deed!

.

.

Is this good practice? No,

not really. Since an LED’s function is not linear and each

manufacturer offerings and types have different operating

current/voltage ratings, any and every LED used may have to have its

resistor values tweaked just right to get a desired result, especially

if you are ganging-up multiple LED’s. Also, you’ll notice by

turning the pot (10K Ohms or more) that first, there is a very tight

area in the rotation when the LED goes from so-so bright to

really-bright, second, it will also seem that after it gets somewhat

dim from more resistance, it seems that even after you add more

resistance, even a lot, it’s hard to extinguish it’s light completely.

This is because an LED can efficiently produce photons from a

very small voltage, especially the Blue ones. An LED is

definitely a non-linear device and for some color combinations

it will be best to apply no resistance or to open the LED element

circuit completely. But there is another method of control

that can come close (see the next circuit.)

.

The values given above are in Ohms. “~”

indicates an open condition. “0” indicates no resistance. Values are

approximate on top of any current limiting

resistance and results are not typical of course, but feel free to try

it out for yourself

This is a question with an obvious

answer, but what can we use a color or brightness controlled RGB LED

(or 'cob' of LED's) for anyway? In two examples in my

experiment, I was able to make an approximation of 'black body

radiators' including incandescent (candle or warm) bulb light and that

of a fluorescent bulb or mercury vapor style bulb (daylight or cool)

light. These would be great replacements for lamps in the

front panels of your vintage radio gear, and they would virtually last

forever. Though, LED's of these colors are commonly available

with just two leads and they are essentially blue LED's with a yellow

phosphor filter layer on top to produce these white-ish

colors. For more colorful uses, I’ve configured RGB

LED’s to change color to reflect the status of various operations in my

homebuilt radio gear. In one QRP amplifier, with its

indicator RGB LED, I used an aqua color when the amplifier was

in standby, and it shined red when it detected RF, which was a good

indicator from a distance. There are reasons for dimming

LED’s too. Many LED’s are manufactured to be extremely

efficient and bright for the energy used and using an extremely bright

LED, dimmed to a low level will allow you to use indicators in certain

circuits where energy consumption should stay low, plus they will last

forever.

Now You Have Control…

Use Pulse Width Modulation to Control LED’s, Motors, Etc.

With the above method, we

attempted to vary the brightness of a non-linear semiconductor LED

device by applying in-series current-limiting resistance.

While it’s practical to go this route for simple

applications, controlling accuracy and efficiency is difficult.

In the following circuit we'll use a common '555'

timer/oscillator IC to control light output by

implementation of pulse width modulation, or PWM. Amateur

Radio operators are familiar with different types of radio frequency

modulation, from amplitude modulation to frequency modulation.

A few rare modes use PWM and so do many class-D and E

amplifier circuits. Those familiar with remote control

devices know about PWM to reproduce control levels at the controlled

device. Though not digital by intended application, a PWM

signal varies the ratio between a signal's high and low levels (called

‘marks’ and ‘spaces’) on a constant oscillation frequency.

Each ‘high’ level often represents a full voltage potential

and the ‘low’s' represent no voltage. When the PWM signal is

averaged out over time a predictable intermediate-level voltage is

obtained, varied by the relationship between marks and spaces.

.

.

PWM voltage control is often used in

power-hungry and high initial current devices such as motors and power

supplies where the device is not efficient or operable at

lower voltage yet varied or lower power or speed is desired to be

produced. By applying quick pulses of full-power into a motor

over small intervals of time, there’s still enough current to overcome

the winding's reactance and the cumulative power to kick the motor’s

windings into operation, yet with less available duration of power you

can spin the motor slower. Without PWM a motor would require

more current to flow to work as opposed to the lower available voltage.

When used in power supplies, a PWM signal at a very high

frequency, when averaged, allows for the supply to save space by using

a smaller power transformer and even transfer more power efficiently

while not wasting some as heat into a tradition linear transformer.

PWM is the preferred method

of light-level control for LED’s... As mentioned above, LED’s

are non-linear devices where the voltage verses current required to

produce an amount of light does not seem to be in concert. By

applying the suggested voltage source to an LED but in small

varied-duration burst, and do this faster than the human eye can see

(due to persistence of vision,) we both satisfy the operational limits

of the LED and provide a way to control the level of (apparent) light

output.

The "Old School" Method...

The easiest and tried and

true method for an experimenter to PWM control an LED is to use the

venerable '555' timer/oscillator IC. In the following

circuit, it's used in an ‘astable multivibrator’ configuration and is

set to around 2 kHz which will pulse an LED on its output quicker than

the eye can see. C1 (.01uF) can be changed to adjust the

timing. The D1 and D2 (1N4148) pair are used to route

charging and discharging through the pot R2 to set the PWM duty cycle,

which again, is the ratio of ‘mark’ and ‘space’ durations within a

repeated block of time. As the 'on' (mark) pulses get quicker

while the 'off' (spaces) get respectively longer, the duty cycle gets

lower, and as they trade durations, the cycle gets higher.

Think of it as a ham operator sitting at their station having

a long 'rag chew'. If they're long-winded their duty cycle

will be higher and their transmitter will run hotter, and if the other

guy is the talker, then vice-versa. More information on

operating the '555' is sure to be found online. As pin 3

outputs the determined PWM signal, transistor Q1 is switched on to

follow suit. By itself, pin 3 of the timer could run an LED,

but it is not suggested. I used a 2N4401 in my experiment

circuit as it can handle up to 600 milliamps which could be up to 20 or

30 regular red LED’s at once if I wanted.

.

.

Can a motor be used instead of an LED?

You can if the motor’s peak-surge current spike does not

breach the max rating of the transistor. Any transistor or

power MOSFET can be used to control whatever it will handle considering

the specs of the transistor or MOSFET to match that of the application.

Again, online examples are available in abundance to help you

get your motors running if you wish. You can gang LED’s in

series and parallel minding whatever type of current protection

resistors are used to properly run those LED’s. And of

course, you can use more transistors to control more transistors if

bulk is desired. There’s another advantage of using PWM, and

that is consistency. Whether at 10% or 90% duty cycle, power

is applied the same if you’re using an LED as it would be a

large motor, so you should be able to host many LED’s of varying types

together to a unified result. You'll still have to consider

the proper current limiting resistor value for the host device's peak

full-on brightness, and because the device's internal heating and

subsequent heat dissipation duration is correlated to the duty cycle,

you'll see a smaller resistor value often used to bring more brightness

to an LED which is designed for low duty cycles such as with

"Charlie-plexing."

Nothing’s perfect, though.

Once you construct this simple 555-based PWM LED control

circuit, you’ll notice a fault right off the bat in that part of the

adjustment range on the pot's sweep doesn’t seem to do anything, and

when you adjust the pot for minimal brightness the LED

doesn’t go completely dark. This behavior is inherit

of the workings of the 555. Because the oscillator,

considering the 555's comparators setup must have something to cycle

with, a 555-based PWM signal usually gives you a range between 5% and

95% duty cycle at best and it is not completely linear due to the

circuit's capacitor charge/discharge curve. This means that

at the bright end of the scale, the LED will not be at its true full

brightness and will be still apparently lit at the low end.

Adding the optional C4, a 0.1 uF capacitor, from the base of

the transistor to ground will allow you to bring the LED to a

completely ‘off’-state at the low end of the control. By

adding the capacitor, the base of Q1 can only switch on according to

the state of charge on C4. Since there is a time factor involved in

charging that capacitor, as the pulses get shorter, the power to Q1

starts to diminish and eventually there is nothing going to the LED.

At this point we are destroying any benefit to PWM and we are

now augmenting the current level through the host LED, plus this will

not work so well on motors or any other high-load device. In

effect, this creates more of a saw-tooth shaped-pulse rather than a

square wave and is more of a pseudo-PWM. You'll have to of

course wire up three of these 555 PWM circuits to get full-color

control of an RGB LED.

The

"New School" Method...

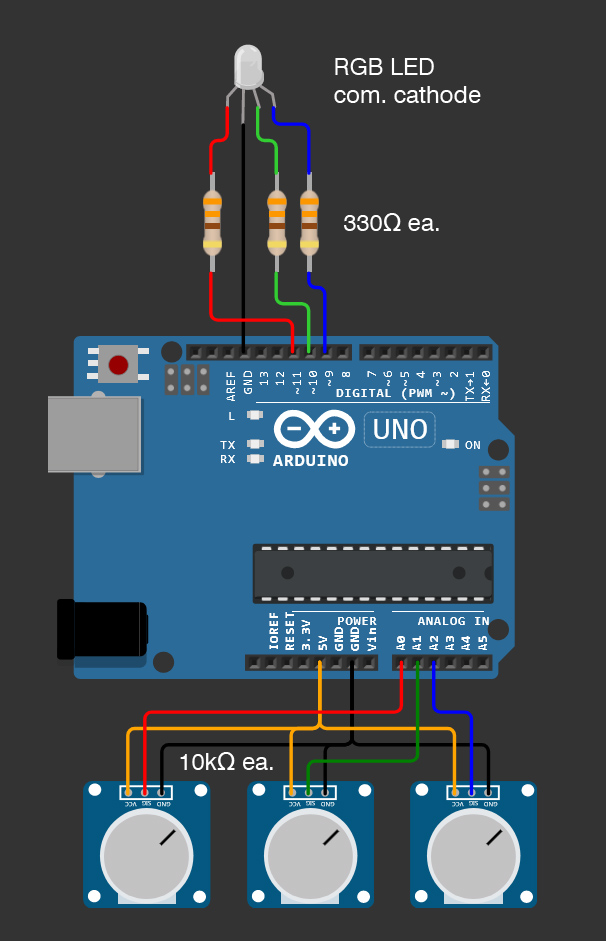

By now, most electronics

enthusiasts and newbie learners have heard of Arduino and the use of

microcontrollers to more easily do any task a conventional discrete

logic circuit could do. All one has to do now is plug an

Arduino development board like the UNO R3 into your PC's USB port,

launch the Arduino IDE software, wire up their RGB LED's color element

anodes to three digital I/O ports of their board in series through

appropriate current-limiting resistors, write and upload a "sketch"

program and "Bob's you uncle!" To go a step further, you can

wire up a WS2811 addressable RGB LED using only one wire for data then

write a sketch with the FastLED library. Well yes, it's that

easy. In fact, we can use the Arduino to upload a

sketch to an even smaller microcontroller IC such as the

ATTiny85 which has the identical shape and pin count as a 555 and get

an exact duty cycle range between 0% and 100% on all three colors!

.

This microcontroller method is pretty

straight forward if you follow the below instructions.:

.

|

|

|

// Sketch for PWM controlling an RGB LED with potentiometer input

// Define the pins for RGB LED

const int redPin = 11; // Red LED connected to PWM pin 11

const int greenPin = 10; // Green LED connected to PWM pin 10

const int bluePin = 9; // Blue LED connected to PWM pin 9

// Define the analog input pins for potentiometers

const int redPotPin = A0; // Potentiometer for red connected to analog pin A0

const int greenPotPin = A1; // Potentiometer for green connected to analog pin A1

const int bluePotPin = A2; // Potentiometer for blue connected to analog pin A2

void setup() {

// Set RGB LED pins as outputs

pinMode(redPin, OUTPUT);

pinMode(greenPin, OUTPUT);

pinMode(bluePin, OUTPUT);

}

void loop() {

// Read the analog values from potentiometers

int redValue = analogRead(redPotPin);

int greenValue = analogRead(greenPotPin);

int blueValue = analogRead(bluePotPin);

// Map the potentiometer values (0-1023) to PWM range (0-255)

int redBrightness = map(redValue, 0, 1023, 0, 255);

int greenBrightness = map(greenValue, 0, 1023, 0, 255);

int blueBrightness = map(blueValue, 0, 1023, 0, 255);

// Set the brightness of the RGB LED using PWM

analogWrite(redPin, redBrightness);

analogWrite(greenPin, greenBrightness);

analogWrite(bluePin, blueBrightness);

delay(10); // Adjust delay as needed for responsiveness

} |

|

| | | | |

.

Shown on the right is an example of an

Arduino sketch that controls a common cathode RGB LED using three

potentiometers connected to analog pins for adjusting the perceived

luminescence of each RGB channel independently. You will need

any Arduino or Arduino clone model such as the UNO R3, the Nano, the

Mega or any related model - keeping in mind the required pin

assignments. You will also need 3 resistors, each anywhere

from 220 ohm to 1k ohm and three potentiometers (variable resistors or

"pots".) The value of the pots is not crucial as the ADC

(Analog to Digital Converter) simply reads the voltage in which the pot

acts as a resistor pad network giving you a selectable voltage between

that of the Vcc (5 volts) and ground potential., but anything between

5k ohms and 100k ohms will be fine. You'll also need some

Dupont style jumper wires.

Copy and paste the sketch

above into the Arduino IDE and upload to your Arduino. Since

this article is about controlling an RGB LED, any training or help you

should require for the setup and operation of an Arduino can be found

readily on YouTube or Arduino.org and is beyond the scope of this

article. It is also possible to use an ATTiny85 but that

requires an extra bit of expertise as only certain pins can be made to

run PWM.

For wiring, connect the

common cathode of the RGB LED to the GND pin of the Arduino Uno then

the anodes of the red, green, and blue LED elements to PWM-enabled pins

11, 10, and 9 respectively. Connect each potentiometer's middle pin to

the analog input pins A0, A1, and A2, and connect their other two pins

to 5V and GND respectively.

The sketch reads the analog

values from the potentiometers, maps these values to a range suitable

for PWM (0-255,) and sets the brightness of the corresponding LED

channels accordingly. Adjust the potentiometers to control the

perceived luminescence of each RGB channel independently.

Upload the sketch to the Arduino and "taste the rainbow" as

they say. (LED's are not Skittles, so keep them out of the reach of

children.) Since this is a microcontroller, feel free to augment and

write your own code! First, try printing to the serial

monitor, the potentiometer ADC values as well as the PWM output values.

You can use any chosen value later on in other projects to

get that perfect color. Next, you can try omitting the pots

and using loops and delays to produce your own little light show.

I would offer more suggestion, but this is a juicy can of

worms you'll never be able to close once you open it!

Addressable RGB LED's...

Using an addressable RGB

LED, commonly known as "NeoPixels," WS2811, WS2812 and etc., with an

Arduino opens up a world of colorful possibilities for lighting

projects. These LED's allow individual control of each LED

within a strip or matrix via one or two wires, enabling a wide and

complex range of dynamic lighting effects. Again, using them

is outside the scope of this article but I'll share a basic primer.

Please refer to YouTube and other sources for better

information. But to begin using them, you'll need a WS2811

LED or compatible addressible LED strip and the FastLED

library installed in the Arduino IDE. Firstly, wire the

WS2811 LED or LED strip to your Arduino. Typically, connect

the data-in (DiN) pin of the LED strip to one of the digital pins on

the Arduino (like pin 6, for instance,) make sure to run a small-value

resistor in series with this line to protect the LED's sensitive

onboard chip input (use a 470 ohm reisitor,) then install the FastLED library by

navigating to the Arduino IDE's Library Manager and searching for

'FastLED' to install it.

.

|

#include

<FastLED.h> // Make sure to install this

library first

#define

LED_PIN 6

#define

NUM_LEDS 60 // Change this number to match the number of LEDs

in your strip

CRGB

leds[NUM_LEDS]; // This is an array that holds color values

for each LED

void

setup() {

FastLED.addLeds<WS2811, LED_PIN, GRB>(leds, NUM_LEDS);

// "WS2811" is the LED type and "GRB" is the part's RGB order

// and on some models you would put 'RGB'. If the

colors are wildly off, consider this the issue.

}

void

loop() {

// We'll just show a simple example...

// Fill the first half of the strip with red color

for (int i = 0; i < NUM_LEDS / 2; i++) {

leds[i] = CRGB::Red; // The FastLED library has a few ways for programming a certain color

}

// from pre-set names, to hue, to r,g,b values.

// Fill the second half of the strip with blue color

for (int i = NUM_LEDS / 2; i < NUM_LEDS; i++) {

leds[i] = CRGB::Blue;

}

FastLED.show(); // This command sends all the color data

down the chain of LED's

delay(1000); // Display for 1 second before changing colors

}

|

|

.

Oh, and NEVER connect the (+) power lead of

addressable LED's to the Arduino's 5v source because you will quickly

fry your Arduino. Connect it's power to an independent source

such as the power supply that runs everything, but make sure to bond

all the ground lines together. Once the library is installed,

you can access various examples and functions provided by FastLED to

control the LEDs. A common starting point is to use the

'FastLED.show()' function to display colors on the LED strip.

For instance, you can set individual LEDs to specific colors

using arrays and loops. There's a neat example sketch with

the FastLED library called the Show Reel which will try out all kinds

of effects on your multi LED strips or panels.

.

.

In this article, I presented

the modern miracle that is the RGB Full-Color LED, some information on

the nature of controlling these devices and presented three levels of

achieving that control. Hopefully, you learned a little as

well or at least are now familiar with the requirements for using RGB

LED's. Each approach shown is applicable to different

problems. You wouldn't need an Arduino board to give you that

perfect shade of aqua blue on a panel LED, but you'll certainly need

one for controlling wall panel arrays of addressable "erga-bleds." (RGB

LED's). The 555 is of course, one of the most useful

building-block parts ever invented and why write and upload a program

to a device powered by a regulated supply if you don't have to?

RGB LED's are really useful in many projects, are cheap as

chips these days and are worth experimenting with.

.

The weekend is here so go and build

something!

.

73! DE Mike, K4ICY MikeK4ICY@gmail.com

.

Edited: 12/03/23

(C) 2013, 2023 Copyright - Michael A. Maynard |

|

Practical Electronics

Projects By Mike, K4ICY

Practical Electronics

Projects By Mike, K4ICY  Practical Electronics

Projects By Mike, K4ICY

Practical Electronics

Projects By Mike, K4ICY